2026 How to Choose the Right Stainless Steel Wire Mesh?

Choosing the right stainless steel wire mesh can be challenging. Factors like mesh size, wire gauge, and material grade matter. According to industry expert John Smith, "Understanding your specific requirements is key to making the right choice."

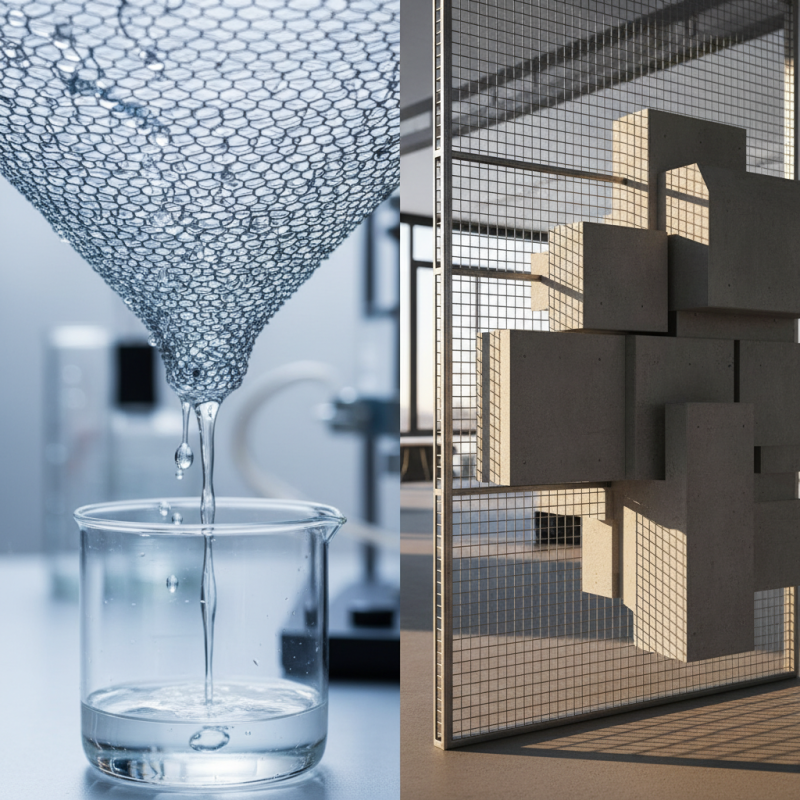

Many buyers overlook how different applications demand unique features. For instance, filtration needs vary greatly from architectural uses. Visualize a process where a fine mesh filters liquid efficiently, contrasting with a sturdier mesh meant for structural support.

It’s also common to feel overwhelmed by options available in the market. Some meshes are perfect for high corrosion resistance, while others lend themselves to aesthetic designs. Reflecting on these aspects can clarify needs. Think of durability versus appearance. Getting it right brings functional benefits, but mistakes can be costly. A thoughtful decision will lead to better outcomes in your project.

Understanding the Basics of Stainless Steel Wire Mesh Options

When choosing the right stainless steel wire mesh, understanding the basics is essential. Stainless steel wire mesh comes in various grades and sizes. Each option has unique properties that affect its application. For instance, the most common grades, 304 and 316, have different corrosion resistance levels. According to industry reports, 316 grade stainless steel is preferred in marine environments due to its superior resistance to saltwater.

Tip: Check the mesh size before purchasing. Smaller openings provide better filtration but might limit airflow. Mismatched specifications can lead to costly oversights.

Consider the construction method. Welded mesh is strong and durable, while woven mesh offers flexibility. Each type serves specific needs. Misunderstandings can arise if the intended application isn’t specified. Tension or load requirements should be considered carefully.

Tip: Always request sample materials before finalizing. This helps assess quality and suitability. Remember, what works in theory may not work perfectly in practice. Make sure to weigh all factors in your decision.

2026 How to Choose the Right Stainless Steel Wire Mesh? - Understanding the Basics of Stainless Steel Wire Mesh Options

| Mesh Type | Wire Diameter (mm) | Open Area (%) | Application | Standard Size (m) |

|---|---|---|---|---|

| welded mesh | 1.2 | 60 | Fencing | 1.2 x 30 |

| woven mesh | 0.8 | 70 | Filtration | 1.0 x 20 |

| perforated sheet | 1.5 | 50 | Grating | 1.2 x 25 |

| expanded metal | 2.0 | 80 | Security | 1.0 x 20 |

Identifying Different Types of Stainless Steel for Wire Mesh

When selecting stainless steel wire mesh, understanding the different types of stainless steel is vital. The most common types include 304 and 316 stainless steel. Alloy 304 offers excellent corrosion resistance and is often used in general applications. In contrast, 316 stainless steel contains molybdenum, enhancing its resistance to chlorides. This makes it ideal for marine environments.

A recent industry report highlights that about 70% of wire mesh applications rely on 304 stainless steel. However, where chemical exposure is a concern, 316 is preferred. This indicates that many users might overlook the specific needs of their projects. When considering the choice, factors like mesh size, wire diameter, and finish must not be ignored. Each contributes to durability and suitability.

Designing a project with stainless steel wire mesh raises challenges. Ensuring compatibility with the intended environment is essential. Mesh that works for one application may fail in another. It’s crucial to analyze factors like temperature and potential chemical exposure. Making the right choice can prevent costly failures down the line. A little reflection now can save significant issues later.

Factors to Consider When Selecting Wire Mesh Specifications

Choosing the right stainless steel wire mesh requires careful consideration of various factors. The gauge of the mesh significantly impacts its strength and application. For instance, a finer gauge mesh is better for filtration, while a thicker gauge is ideal for security applications. The mesh opening size is also crucial. Smaller openings provide better containment but can impede airflow. Conversely, larger openings enhance drainage but might not support small particles.

Tips: Always verify the requirements of your project. Different projects demand varying specifications of wire mesh.

Material composition affects the mesh's corrosion resistance. For environments exposed to chemicals, a higher chromium-nickel alloy is recommended. This allows for durability over time. Research shows that stainless steel mesh with at least 10.5% chromium exhibits significant corrosion resistance.

Tips: Conduct a tensile strength test. This is important for ensuring the mesh meets your strength requirements.

Also, think about the finish. A smooth finish prevents the build-up of debris, while a textured surface can increase grip. Choosing between these finishes largely depends on the intended application. Regularly assess whether your chosen specifications continue to align with your actual needs. Sometimes, over-preparation can lead to wasted materials or excess costs.

Evaluating Mesh Size and Weave Patterns for Your Needs

When choosing stainless steel wire mesh, evaluating mesh size and weave patterns is crucial. The mesh size refers to the number of openings per inch. For example, a 100 mesh means 100 openings in one inch. Smaller openings filter finer particles. Consider the application—whether it’s for filtration, security, or architectural design. Each application demands a specific mesh size.

Weave patterns also play a significant role. Plain weave offers strength and durability, making it a popular choice for many industrial applications. Twill weave provides flexibility and allows better flow, ideal for certain filtration tasks. Each pattern alters the mesh's characteristics. Think about what you need.

Choosing the right combination can be challenging. Not every size or pattern will suit your project perfectly. Experimentation may be necessary. It’s vital to analyze how different materials interact. Sometimes, the ideal choice isn’t obvious at first. A careful examination is essential to ensure the mesh meets your specific requirements.

Stainless Steel Wire Mesh Size and Weave Patterns Evaluation

This chart displays the comparison of various stainless steel wire mesh sizes and their corresponding weave patterns suitable for different applications.

Applications and Industries for Specific Stainless Steel Wire Mesh Types

When choosing stainless steel wire mesh, understanding its applications is crucial. Different industries require specific types of mesh based on their unique needs. For example, in the food industry, a finer mesh may be necessary to prevent contamination. This mesh also needs to be easy to clean and corrosion-resistant.

In construction, heavier gauge mesh is often used for strength and durability. It can be found in concrete reinforcement. The mesh also serves to prevent soil erosion in landscaping projects. In both cases, the right choice impacts effectiveness and safety.

Consider the nuances of each application. Sometimes, selecting the wrong specifications can lead to costly mistakes. A wire mesh that is too coarse may not provide adequate safety. Alternatively, overly fine mesh may result in blockages or inefficiency. Understanding these details is essential for optimal usage. Reflecting on past choices can provide valuable insights for future projects.